MRF Quality Certifications & Approvals

Aerospace Quality Management System: AS 9100 & ISO 9001

Mirage Rebuild Factory is the first military institution in Pakistan to acquire ISO 9001 QMS Certification in year 1996. Afterwards, it got certified on AS 9100 Certification applicable for Aviation, Space and Defense Organizations. Since Year 2004, it has retained AS 9100 Certification status without any suspension and is currently certified on AS 9100 Rev ’D (Latest Revision).

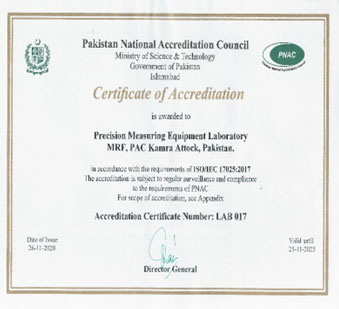

Lab Quality Management System: ISO 17025

MRF is established with ISO 17025 Certified PMEL Laboratory used to ascertain dimensional and measurement accuracy of mechanical, electric & electronic measurement PMEs used at its facilities. It also extends the facility to other customers seeking calibrations services under ISO 17025 certification approval.

Facility Certifications

- Mirage III/V overhauling certified by Dassault Aviation

- Leonardo certification for Depot level maintenance of all Military variants of Augusta Westland AW-139 helicopter

- Mirage pressure Refuelling (MPR) air to air refuelling modification facility certified by Aerosud

- SMartin Baker certified facility for overhaul of MK-4 and OM-6 Ejection seat for Mirage (III/V) Aircraft

- Oxygen system overhauling facility recognized by Zodiac Aerospace

- Hose Manufacturing Facility certified by Hydropneu Technologies

- AS9100B ISO 9001-2008 and CAA certified CNC Pipe bending facility to manufacture copper brass, Aluminium and SS material pipes for various aircraft systems

OEM Approvals

- SNECMA (France) : ATAR 09C Engine MRO

- Rolls Royce : T-56 AMOF (Authorized Military Overhaul Facility)

- Honeywell Aerospace: TFE-731-2A-2A AMOF (Authorized Military Overhaul Facility)

- Aero Turbine USA : Teledyne Continental J69 AMOF(Authorized Military Overhaul Facility)