PAC is proud of its reputation for manufacturing high quality, leading technology products. Rework of Printed Circuit Boards (PCBs) is kept to a minimum and overall yields maximized by implementing a closed loop process control. Defects are reported, analyzed, and addressed in a closely monitored cycle that ensures prompt correction. Therefore, our electronics production lines can consistently deliver high standard of quality.

PAC can provide customers adequate testing of their products. These include full functional testing and in-circuit testing. Our desire is to provide our customers with the highest quality production of their products.

Following services / equipment are available for functional and in-circuit testing of products.

Functional testing

- Analogue testing

- Digital testing

- Bus testing for RS 232 / 422,

ARINC 429 and Mil-Std 1553B

- RF Testing

- Power supply testing

Equipment available

- S9100 series functional test station

- RF test station

- Power supply test station

In-Circuit testing

- Analogue devices

- Digital devices

- Hybrid devices

- Wiring / loom / cables testing

Equipment available

- SE8862 in-circuit test station

- MTS-500 flying probe test station

- DIT-MCO cable test station

Teradyne Functional Testing

Teradyne In-circuit Testing

Condor In-circuit Testing

Power Supply Tester

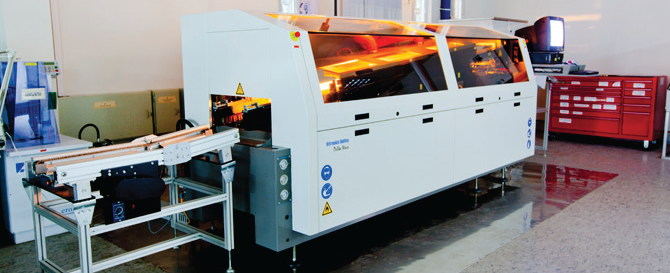

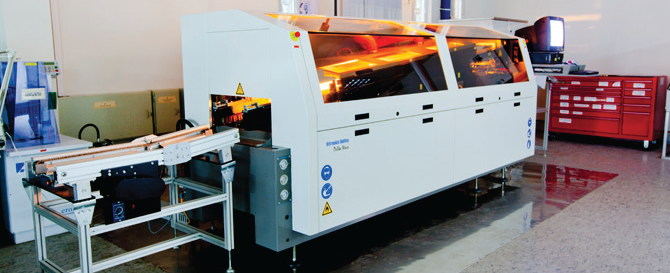

Pakistan Aeronautical Complex (PAC) has state of the art setup for PCB stuffing of both Surface Mount Technology (SMT) and Through Hole Technology (THT) components. The facility includes optical inspection, X-ray inspection, PCB treatment (PCB Washing, Ionic contamination testing, Conformal coating etc.), Functional Testing, In-circuit testing (ICT) and Environmental Stress Screening (Component to System level). PAC provides comprehensive service in the mentioned categories and has gained rich experience with customer satisfaction. We can handle high volume and prototype quantity. We adhere to IPC standards and are AS 9100-C certified.

Automatic SMT Stuffing Facility

Automatic SMT Stuffing Facility

THT Stuffing Line

Manufacturing Services

- Stuffing for through hole and surface mounted devices (SMDs) in accordance

with quality standards IPC-A-600H and IPC-A-610E.

- Prototyping and high volume production

- Single type or hybrid stuffing process

- Repair & Rework

- Programmable, hot-air based and IR based rework system

- Mil Std 810-D compliance

- Conformal Coating for humidity and environmental control

- Optical and X-ray inspection

|

|

- ESS (Vibration, Thermal Vibration, Climatic, Thermal Altitude, Thermal Shock)

- Polymer based potting of high voltage power supplies by vacuum suction method

- Assembly of cable harnesses and winding of transformers

- ESS profiling and testing

- Single axis random vibration systems

- Fabrication of interconnection aircraft looms

- Production from base level i.e. from completely knocked down and semi knocked down kits.

|

Conformal Coating

Conformal coating is an extra cost operation. Boards not in standard panel size will require additional tooling. Humiseal Coatings and Silicon types of conformal coating can be offered. Conformal coating is done as per coating map provided by the customer to meet the product requirement. Coating map is to include thickness of coating and no coat areas and components.